But how is a monoblock actually made? What happens from the moment an order arrives at Kromet to the moment when shiny steel becomes the heart of a professional kitchen?

Let’s follow the process step by step — from raw material to the finished product that ends up in the hands of the most demanding chefs.

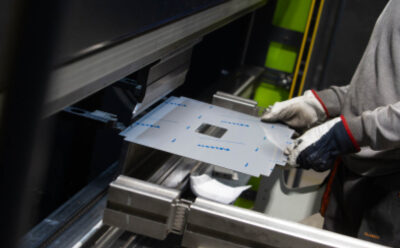

Stage 1: A sheet of steel — the beginning of every monoblock

Before any burner ignites, before the oven starts heating up, before the first pot lands on the hob — it all starts with… a sheet of steel.

And not just any steel. At Kromet, we use high-quality stainless steel that exceeds market standards in terms of thickness. This choice is dictated not only by durability, but also by the everyday realities of working in the catering industry: high temperatures, humidity, intensive cleaning, and continuous use.

The sheets are laser cut and precisely formed using CNC technology. Millimetres determine whether the final hob will fit into the worktop without any gaps. For us, this precision is fundamental – because at this stage, we are creating something more than just a structure. The philosophy of the chef who will soon be standing at this steel block is created.

This is also the moment when our designers and technologists already have a picture of the final monoblock in their minds: its ergonomics, the spacing of appliances, water and electricity connection points, and even whether it will look good in an open-plan kitchen.

As Wiktor Tusiński, Sales Director, admits:

We have never produced two identical monoblocks.

Every sheet, every cut, every bend is the beginning of a story that will end in a restaurant kitchen. And there is no room for compromise there.

See this in the example of our project. Read the post about how our product was created: Kromet monoblock in the heart of 4 Winds Resort & Spa →

Stage 2: Welding, forming, joining – the heart of the monoblock

At this stage, the raw, precisely cut material begins to resemble the finished product. This is the moment when steel becomes a monolith. In the literal sense of the word.

The monoblock from Kromet is not a set of devices placed next to each other, but a uniform block in which cookers, fryers, ovens and bain-maries are seamlessly built into a smooth work surface. This effect is achieved through an advanced welding and grinding process — performed manually by experienced production workers.

Every weld matters. Although they are almost invisible from the outside, their role is crucial: they connect all the elements into a whole that is resistant to overload, moisture, high temperatures and tens of thousands of services per day.

An integrated worktop is not only aesthetic, but above all hygienic. No gaps means no place for dirt and bacteria to accumulate. It also means easy cleaning – one wipe with a cloth instead of tedious dismantling of appliances.

The monoblock design is fully customisable, which means that all kitchen needs are taken into account at this stage – from worktop heights to the placement of drains, sockets, gas and electrical connections. As a result, the appliance not only works, but is also convenient, ergonomic and consistent with the team’s work rhythm.

This is also a time for cooperation between the design and technology departments and customer advisors. Questions arise: Where will the tilting pans be placed? Should the salamander have a lowered worktop underneath? How many GN containers will the cooler hold and should the front be open or closed? The answers become real design decisions — and all this before any heating device is installed in the monoblock.

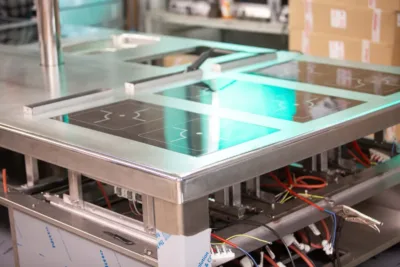

Stage 3: Installation of heating and control devices — technology at the service of the kitchen

Once the steel monoblock structure is ready — refined in every detail, gap-free, solid as a fortress — it is time to breathe life into it. This is when heating devices, control systems, electrical and hydraulic systems come into play. This stage can be compared to installing an engine in the body of a sports car — these are the elements that will determine the power, precision and comfort of driving.

The key word? Modularity. At Kromet, we offer enormous configuration possibilities. The investor and chef can work with the designer to select the elements that are really needed: from gas cookers, through induction hobs, to deep fryers, tilting pans, stools, ovens, and even bain-maries, coolers and salamanders.

Each element is embedded in a monoblock so that it works flawlessly and is convenient for everyday use:

- heating plates fit precisely into the worktop, creating a uniform surface;

- gas and electric ovens (including convection ovens) have thermally insulated doors and efficient heaters;

- deep fryers and boilers have built-in drains, temperature controls and cold zones;

- control panels are mounted at the front, within easy reach, always in a location that is intuitive for the user.

Ergonomics is the key word. We know that even the best-equipped kitchen will not fulfil its role if it is uncomfortable. That is why each monoblock is designed to reduce chefs’ movements, facilitate their cooperation and eliminate unnecessary downtime.

Importantly, Kromet monoblocks combine different power sources. You can integrate gas cookers with an electric oven, combine an electric fryer with a gas grill in one unit, adapt the appliances to propane-butane or power the whole system from a single technical switchboard.

Thanks to the fact that everything is already in place and internally connected in the monoblock, only a few connections are needed at the installation site. This not only means convenience and order, but also saves time and costs during installation on site.

Stage 4: Quality and ergonomics testing — the fire trial (literally)

A finished monoblock is more than just steel and technology. It is trust — and that trust must be justified. That is why, before any device finds its way into a customer’s kitchen, it undergoes a series of rigorous tests that are not visible in the catalogue, but can be felt during every shift.

Tests for tightness, stability and connections. Every valve, every weld, every electrical connection is checked for safety and durability. At Kromet, we know that a commercial kitchen does not forgive mistakes — everything here must work immediately, reliably and under extreme conditions.

Temperature and heating uniformity control. This is the stage at which heating devices show their capabilities – they are tested for efficiency, heating speed and control accuracy. In the case of ovens and grill plates, for example, a constant temperature across the entire surface is important – and at Kromet we are able to ensure this thanks to DUAL ZONE technology and selected components.

Ergonomics and ease of use tests. This is perhaps the most underrated but crucial stage. Production and R&D staff analyse how a chef will use the monoblock: whether the handles get hot, whether the control panels are in the right place, and whether the whole unit forces unnecessary movements.

As Jacek Grochowina, chef and owner of the Nolita restaurant in Warsaw, says:

‘A monoblock is the best way to organise work and keep things tidy. It is the heart of the kitchen, around which all sections operate and the entire service takes place.’

It is thanks to such opinions — and the fact that the tests are conducted in cooperation with catering professionals — that Kromet monoblocks are gaining recognition in the most demanding markets. They are not a catalogue product, but a specific response to the real needs of chefs.

From production to your kitchen

A Kromet monoblock is not an off-the-shelf product. No two models are the same, and you cannot buy one in five minutes. But if you are creating a kitchen where time, cleanliness, order and efficiency are of the utmost importance, this is the solution for you.

Every monoblock that leaves the factory in Krosno Odrzańskie is the result of cooperation between a designer, an engineer, a salesperson and… a chef. Because only then can you create a device that not only works, but also really improves the work of the whole team.

If you are planning to invest in a kitchen:

- for a hotel that serves hundreds of guests a day,

- for a restaurant with an open kitchen where the equipment is on display,

- for catering, which must be fast, reliable and mobile,

- or you simply want to create a comfortable, ergonomic workplace where your chefs can focus on what matters most — taste,

…then a Kromet monoblock may be the best investment decision you will ever make.

Order a design. Talk to an advisor. Start with a vision.

Write to us: handlowy@kromet.com.pl

Or maybe you already have a kitchen plan? Send it to us and our specialists will prepare an individual monoblock design for you.